BATTERY RECYCLING

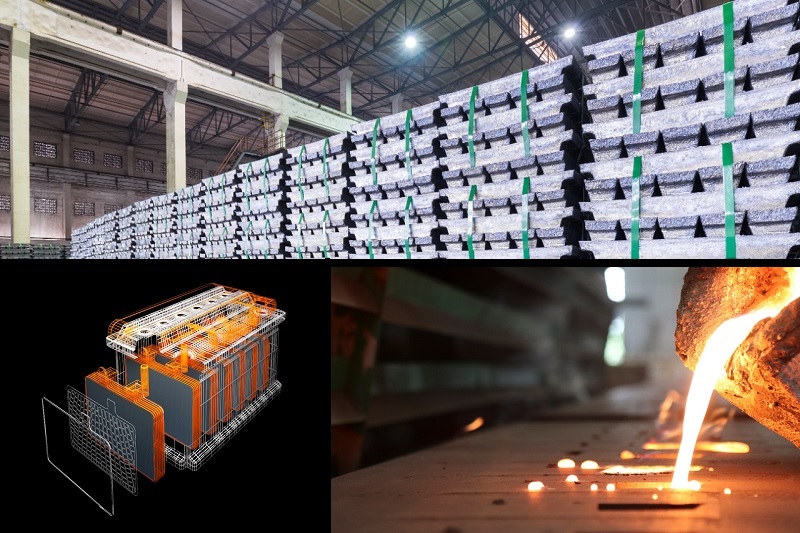

Calorpyro is committed to it’s role as a battery recycler. As the world’s largest producer and recycler of lead (1 million short tons of secondary and lead production in EU, US and RSA) Calorpyro is currently the only global company offering a closed recycling loop for lead-acid batteries.

Our production facilities use the latest cutting-edge technologies to ensure high quality, efficient and environmentally responsible products which are renowned for their consistency. All our operations are certified according to ISO 9001, ISO 14001, ISO 50001, OHSAS 18001 or EMAS standards.

WHY CALORPYRO

- 80% of the lead used in our production process is recycled.

- The only global company offering a closed recycling loop for lead acid batteries.

- Proudly the world’s largest producer and recycler of lead.

OUR LEAD RECYCLING PROCEDURE

- Lead is extracted from a multitude of materials, including scrap lead. Some of the lead comes from off cuts and waste from the manufacturing process.

- Once extracted, the scrap lead is heated in kettles at 450°C. At this temperature, the lead melts and any impurities rise to the surface.

- The impurities are removed and sent off for further processing.

- The final part of the process is to refine the lead to achieve a lead alloy of 99.9% purity.

Calorpyro is committed to it’s role as a battery recycler. As the world’s largest producer and recycler of lead (1 million short tons of secondary and lead production in EU, US and RSA) Calorpyro is currently the only global company offering a closed recycling loop for lead-acid batteries.

Our production facilities use the latest cutting-edge technologies to ensure high quality, efficient and environmentally responsible products which are renowned for their consistency. All our operations are certified according to ISO 9001, ISO 14001, ISO 50001, OHSAS 18001 or EMAS standards.

WHY CALORPYRO

- 80% of the lead used in our production process is recycled.

- The only global company offering a closed recycling loop for lead acid batteries.

- Proudly the world’s largest producer and recycler of lead.

OUR LEAD RECYCLING PROCEDURE

- Lead is extracted from a multitude of materials, including scrap lead. Some of the lead comes from off cuts and waste from the manufacturing process.

- Once extracted, the scrap lead is heated in kettles at 450°C. At this temperature, the lead melts and any impurities rise to the surface.

- The impurities are removed and sent off for further processing.

- The final part of the process is to refine the lead to achieve a lead alloy of 99.9% purity.